Data-powered automotive warranty re-invention

At first glance, it appears to be a bad way to woo customers—a warranty process that’s used when things go wrong. Instead, it turns out to be an excellent opportunity for a company, not just to please its customers, but also to radically improve its business processes and find sources for future growth. For the automotive industry, as the traditional ownership model declines, companies are hungry for new revenue streams.

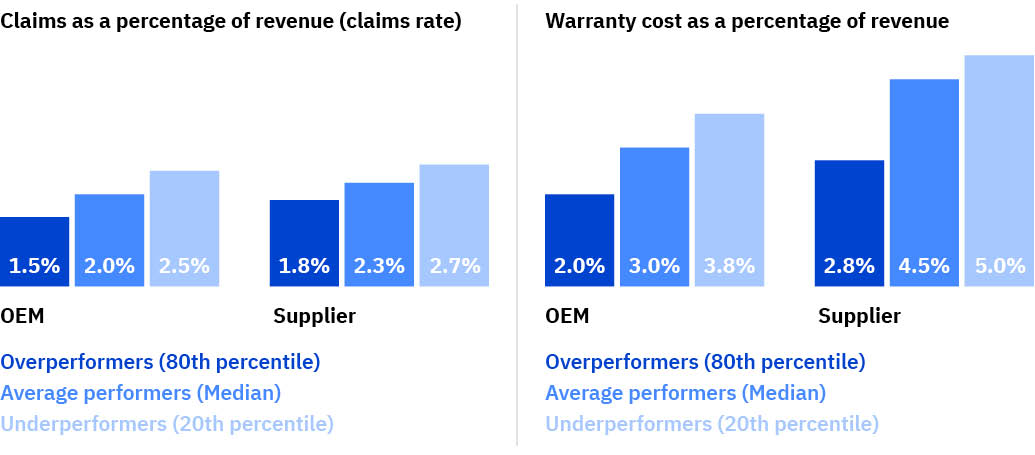

Recent IBM Institute for Business Value research found that on average, automotive original equipment manufacturers (OEMs) spend 2 percent of their annual revenue on paying warranty claims (claims rate). Their total warranty costs, including operations, are closer to 3 percent. For suppliers, these costs are 2.3 percent and 4.5 percent, respectively (see Figure below). The opportunity for improvement is significant.

But excessive warranty costs are only part of the picture. Money earmarked for warranty reserves to cover those costs can be substantial and difficult to accurately predict. To get a better sense of the issue, consider that, in 2018, total claims for global auto manufacturers were USD 56 billion, while they had USD 115 billion in reserves.

While cost reduction efforts can improve automotive company profitability, there is also value to be gained on the other side of the ledger. For example, one major auto OEM uses warranty data to improve its claims process and forecast parts usage. Time to identify non-compliant claims has decreased from three minutes to less than a minute, helping reduce labor costs by 52 percent.

But perhaps more important, forecasting parts usage allows the manufacturer to make sure dealers have in-demand parts available for repairs, making it more likely customers have an excellent experience and don’t experience frustrating delays. Insights from warranty data can thus increase customer satisfaction.

What is data-powered warranty reinvention?

Analysis of warranty data can deliver benefits that extend beyond the warranty function. By integrating Internet of Things (IoT) technologies into manufacturing processes, and applying artificial intelligence (AI) and advanced analytics to the data they generate, automotive companies can gain valuable insights into their operations, products, suppliers, and customers. This can lead to the redesign and improvement of existing warranty processes and operations, customer experiences, actual products, and the workforce methods that produce them.

Meet the authors

Dr. Peter Korevaar, Executive IT Specialist at IBMVerena Elisabeth Hafner, Managing Consultant, Advanced Analytics and Optimization, Global Automotive CoC IBM Consulting

Download report translations

Originally published 26 May 2020