The current situation with COVID-19 and its impact on the global economy has dwarfed all previous disruptions. The International Monetary Fund (IMF) calls it "a crisis like no other."

The impact of COVID-19 on the Manufacturing and Resources industry varies from moderate to severe, depending on the downstream customer demand, workforce availability, supply-side shocks and regulatory environment. Industrial original equipment manufacturers (OEMs) are experiencing massive decline in new product demand and a slowdown in the services business, while the Metals and Mining industry is cautious. The Chemicals industry is re-prioritizing its product mix to support demand for alcohol (sanitizers) and plastics for packaging. In the near term, there was some tailwind for the Resources industries due to increased uptake by China, but this seems to be a short-term phenomenon.

At IBM, we see the Manufacturing and Resources industry as an ecosystem of makers and operators whose value chains are intertwined, thus creating an opportunity for enterprises to support each other through these troubled times. For example, industrial OEMs can help their customers provide digital insights and augmented intelligence to maintain optimum operations while their own experts may not be available.

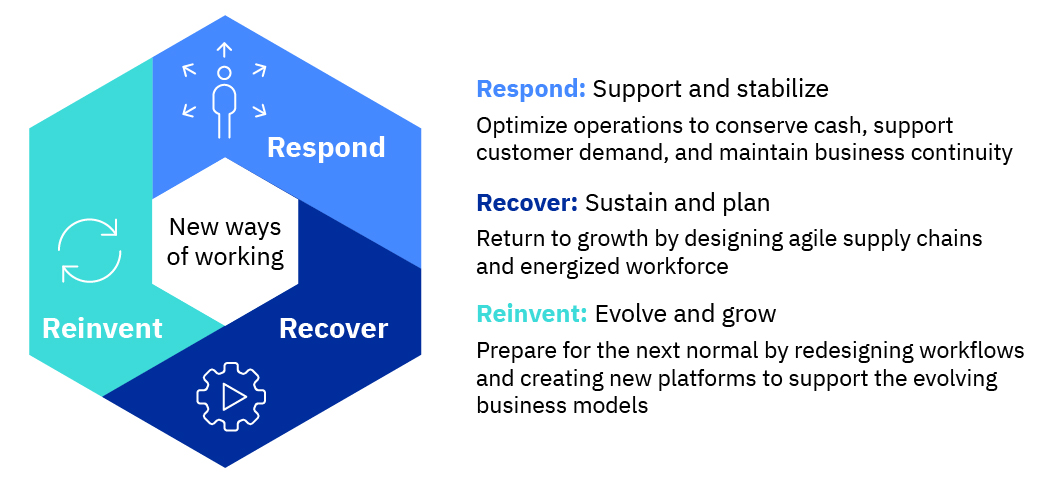

While the immediate need is to maintain continuity of operations and support the community, enterprises are utilizing this phase to prepare for a fast start and develop a long-term strategy to evolve into the next normal. Enterprises are working on a three-step approach to manage the journey: respond, recover and reinvent.

Respond

As we write this blog, enterprises have already initiated actions to respond to the COVID-19 challenge. Most companies in the Resources industries have prioritized community and workforce health and safety. As an example, Tata Steel, through Tata Steel Foundation (TSF), recently launched a ten-point #CombatCovid19 program to empathize with, empower, and equip communities.

Many of our clients are working with us to maintain continuity of operations by:

- Enabling location-agnostic work platforms to empower remote workforces

- Protecting against new cybersecurity risks – from early March to early May, IBM X-Force observed a more than 6,000 percent increase in coronavirus-themed spam.

- Reducing operational cost and maintaining supply chain continuity.

For example, one client, a global manufacturer of eye contact lenses, remodeled its supply chain amid the pandemic. During normal operations, the supply chain ended at the distributor/clinic from which customers picked their orders. During lockdown, this was not sustainable and resulted in loss of revenue. The IBM team worked with the client to automate and integrate order management with the logistics provider to enable direct delivery, thus maintaining order fulfilment and delighting the client’s customers.

Recover

Having managed through the initial shock and assessed the magnitude of impact, enterprises are preparing for a fast restart. They need to focus on critical areas, including:

- Responsive supply chains – Monitor the changing demand and supply picture and the capability to respond in real-time. Forecasting models will be recalibrated beyond statistical methods.

- Differentiated customer engagement – Understand customer needs and provide individualized engagement across all channels. Digital will become mainstream even in B2B engagements.

- Resilient systems and control – Assess risk, execute data-based decision making, and implement extreme automation built on a scalable and secure infrastructure. Enterprises may consider outsourcing non-core processes and collaborating with ecosystem partners to exploit economies of scale.

- Scalable production operations – Ready to restart operations with reliable assets, secure work environments, and availability of resources.

- Enabled workforce – Provide employees with the right skills, tools, and technologies to perform at the best of their ability. Enable lone worker safety to comply with social distancing regulations.

Reinvent

We believe the future of Manufacturing and Resources industries will be hybrid: Supply chains will be a hybrid between global and local. Manufacturing will be a hybrid between traditional and additive. Products and services will be a hybrid between physical and digital. Workforce will be a hybrid, with humans augmented by cognitive machines.

In the long term, enterprises will have to develop next-generation business models by leveraging new technologies and exploiting their core strengths. They will have to focus on:

- Service-enabled business models. Customer experience and service excellence at the core of all business models, commercials linked to outcome-based business models

- Extreme automation to support new ways of working. All workflows utilize data and automation to self-discover and respond to events, with human interaction for exception management

- Digital-first enterprise architecture. The next normal will accelerate the infusion of exponential technologies like artificial intelligence (AI), blockchain, automation, Internet of Things (IoT), 5G, and edge computing into the standard business architecture. Built on the hybrid cloud, this architecture will allow enterprises to exploit the full potential of data and enable new business models.

- New collar talent. A workforce skilled to work alongside cognitive machines and within intelligent workflows is essential.

This will drive acceleration of digital transformation and faster adoption of Industry 4.0.

We aim to come out of this pandemic stronger and ready for the next growth cycle. The ease of the journey will depend on collaboration with the ecosystem and willingness to change.

IBM’s global team of experts is delivering new business insights to help our clients navigate disruption and prepare for the future. Click here to access our COVID-19 Action Guide and related resources.

Meet the author