About cookies on this site Our websites require some cookies to function properly (required). In addition, other cookies may be used with your consent to analyze site usage, improve the user experience and for advertising. For more information, please review your options. By visiting our website, you agree to our processing of information as described in IBM’sprivacy statement. To provide a smooth navigation, your cookie preferences will be shared across the IBM web domains listed here.

The critical role of asset lifecycle management in an interconnected, autonomous world.

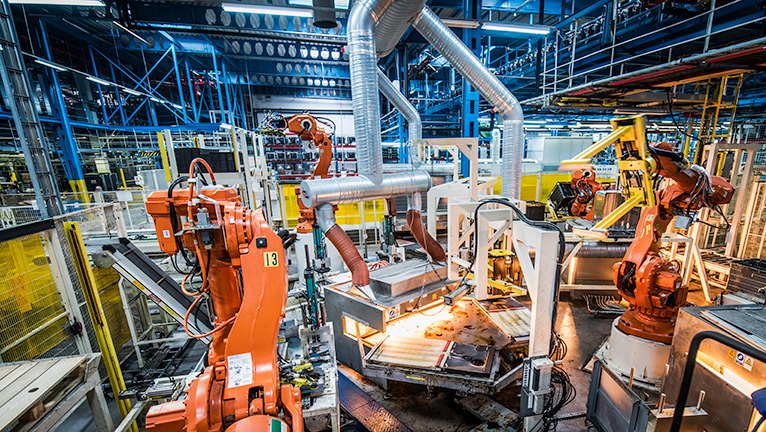

Across every asset-intensive industry — such as energy and utilities, oil and gas, manufacturing, and transportation — organizations are challenged with how to maximize asset value throughout their lifecycle during technology, human capital and economic inflection points. To further complicate matters, current technology infrastructure generates more data, which requires effective systems to filter the noise and focus on what matters most.

Asset performance and the quality of an organization’s products and services are impacted by the reliability of the asset or equipment. Reliability is dictated by the consistency of outcomes, which is nearly impossible with applications and data being kept in silos. As a result, the increased need for a more intelligent approach to asset maintenance and management can have a direct impact on customer satisfaction and financial performance. In fact, in a recent Chief Supply Chain Officer study conducted by IBM Institute for Business Value, 47% of the respondents said they’ve adopted new technologies, including automation, as a response to disruption. The journey to reliability is built on the consistent data, workflows and process that asset management and maintenance platforms deliver.

Despite these challenges, your organization’s strategy must constantly evolve to meet customer demands such as increased global commoditization and competition, compliance with industry and government regulations, resilient and sustainable operations, human capital evolutions, health and safety in the workplace, and the reality of higher costs of doing business.

The ability to adapt to change by improving operations can mean the difference between prosperity and survival, asset lifecycle management, driven by a unified strategy that puts data, analytics and automation at its core, and is extensible to incorporate articificial intelligence/machine learning, IoT and even AR technologies, can have a significant impact. With pragmatic strategy in place, you can optimize production and service systems to the asset, resource, and even the activity level. As a result, your business can wield greater control of the complex asset environments necessary for bottom-line results.