More than a hundred million lines of code. That’s what goes into the design and manufacturing of today’s vehicles. Our cars have become so incredibly software-driven in recent years that the only thing more complex may be the people who operate them.

Seizing on the advanced capabilities of the Internet of Things (IoT), Artificial Intelligence (AI) and machine learning, automotive engineering is changing the automotive industry in ways that were once unimaginable.

Self-driving cars make navigational decisions. Computerized systems detect future failures. Controls adapt to the user’s preferences. Accurate, real-time geospatial information streams into the cockpit. Infotainment systems rival those in the home. And beneath the hood, new hybrid or electric motors promise greener and sustainable alternate vehicles. Under this advanced technology, is another layer of sophisticated software that operates and synchronizes every function.

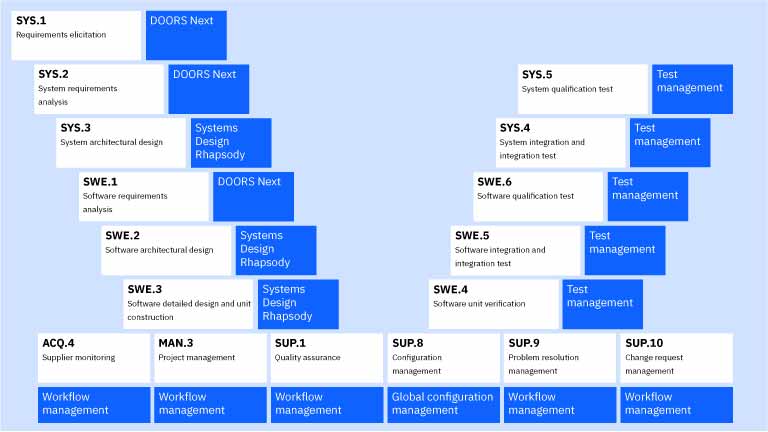

As you would imagine, the development of these automotive engineering advancements has precipitated the need for tougher industry standards. Standards that span process, safety, and emerging AI/Over-the-Air (OTA’s) updates. Adherence to standards such as Automotive SPICE (Automotive Software Performance Improvement and Capability dEtermination) – commonly known as ASPICE – is now not only advised, but has become a mandate. This presents a challenge to automotive engineers throughout the world. How do you comply with exponentially increasing sets of standards, created by numerous governing bodies, with requirements that could make your products prohibitively expensive?

Data drives automotive processes

- Connected cars process up to 25 gigabytes of data per hour1

- Car software may be over 100 million lines of code2

- Connected car market is predicted to reach more than USD 219 billion by 20253

The route requires a new map

- 50% of automotive executives say that digital reinvention is required to succeed—or even survive—today and in the future4

- 72% of automotive companies surveyed say innovation is one of the most important attributes for defining their competitive advantage4

- 74% of automotive organizations apply AI to uncover new insights4

See how Mercedes-Benz underwent digital transformation to automate processes amid growing complexity.