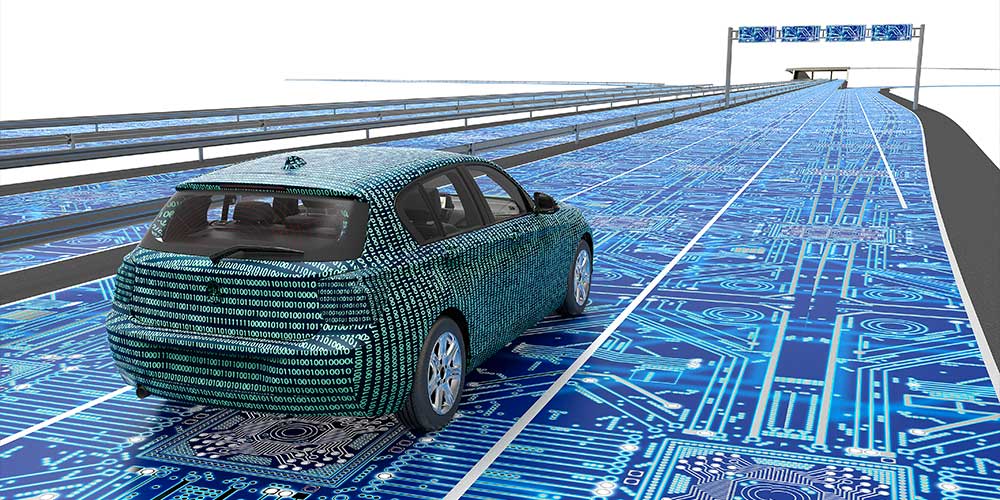

Today’s cars have about 30,000 parts and more than 100 million lines of code 1

of failed projects are due to poor requirements 2

Three key areas are driving the digital transformation in automotive engineering

+

of auto industry executives expect non-traditional participants to have a key role in the automotive ecosystem by 2025 3

The path forward for automotive organizations

Digitization

Improve efficiency by applying technology to individual resources or

processes

Digital transformation

Produce consumer experiences that support individuals’ needs or

wants

Digital Reinvention

Create revenues and results via innovative strategies, products

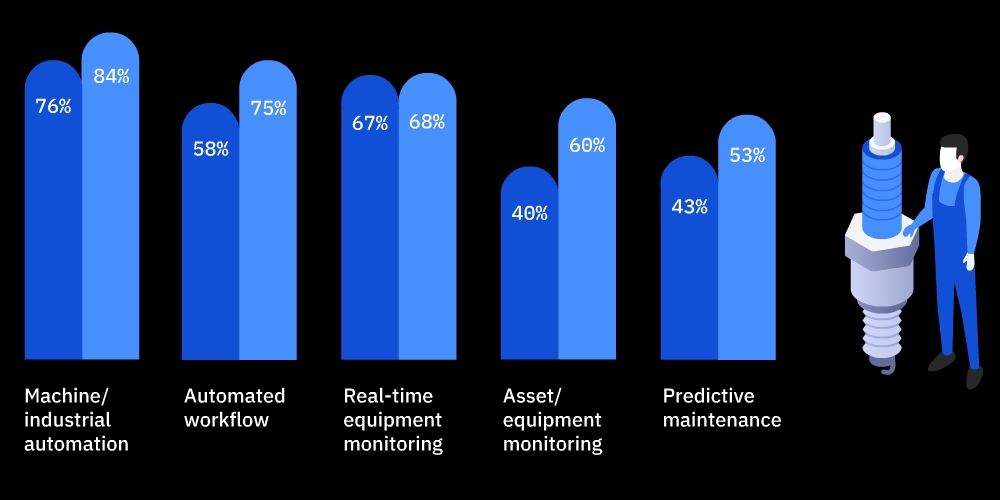

Auto makers and suppliers have already adopted cloud-based engineering tools into their operations

OEMs Suppliers

Yet many are still lacking deployment in critical areas, including security 3

0%

are deploying without risk evaluation

0%

do not perform regular security assessments

0%

do not have a formally established security program

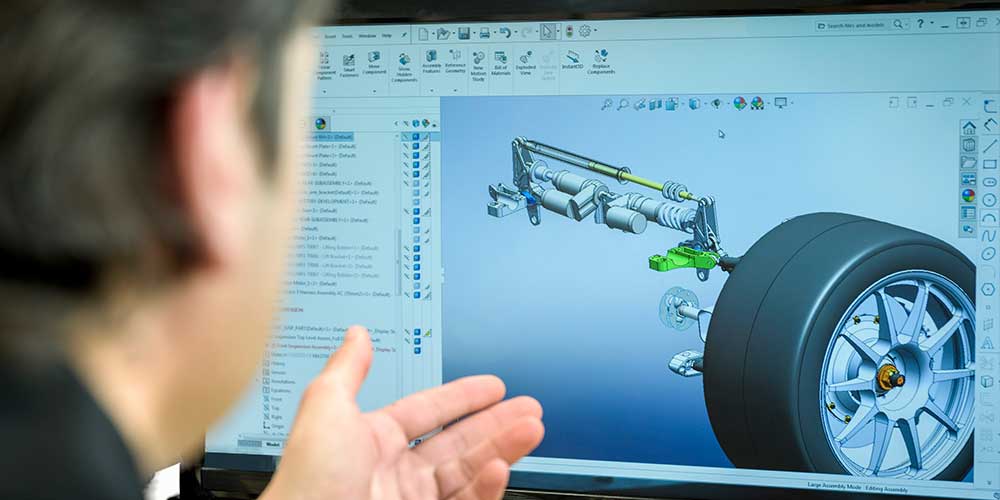

To seize the digital transformation in auto engineering, you need the right mix of tools and practices, both human and machine

Cloud-based

Analytics

Traceability

Modeling

Security

Agile

Teams who embrace these methods will find:

New focus

Systems approach to build in efficiency

New ways to work

Collaborating in real time across globally distributed

teams

New ways to work

Collaborating in real time across globally distributed

teams

New expertise

Leveraging models and AI for continuous improvement

Putting it all into motion

Client study:

Daimler is shifting from traditional truck manufacturing to building digitally connected smart commercial vehicles designed to make trucking more efficient and cost effective.

Building new expertise around IoT, AI, cognitive automation, big data, telematics and hybrid systems, Daimler is creating new services and digital solutions.

It is also rapidly evolving its manufacturing processes, as it reinvents the end-user experience across the commercial vehicle segment.

![]()

Features of the reinvented vehicle

Self-integrating

Digital

integration

Seamless

Secure

Self-configuring

Digital

personas

Personalization

Environmental

Self-socializing

Social

networks

Assisting others

Using vehicles to do other things

Self-driving

Automated

Autonomous

Self-learning

Occupants

Performance

Behavior

Cognitive

Self-healing

Analytics

Prognostics

Servicing

Design smarter cars, deliver new capabilities and enhance customer experiences